Sponsored article

Innovative Technologies in Sheet Metal Deburring Machines – What to Know

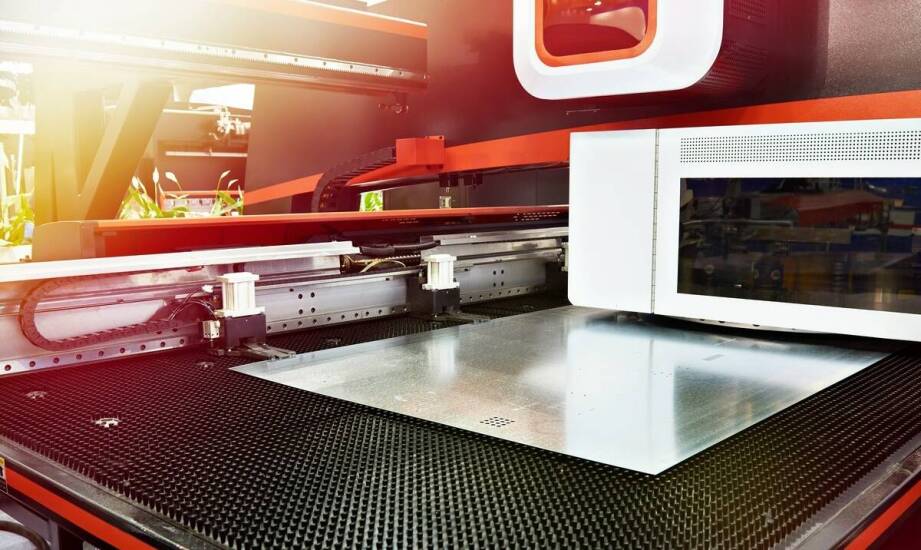

Innovative technologies in sheet metal deburring machines are revolutionizing the processing industry by enhancing the efficiency and precision of processes. Modern solutions bring benefits to users, which is crucial for companies striving to improve product quality. Understanding these technologies allows for better utilization of the equipment's potential, translating into increased market competitiveness. It's worth noting that implementing innovations in this area can significantly impact the efficiency of production processes.

Read more: Key features that mats for heavy use in public places should have

Key Information About Innovative Technologies in Deburring Machines

Innovative technologies in deburring machines offered by Madora significantly improve the efficiency and precision of processing operations. A wide selection of machine models tailored to the specific needs of customers enables effective sheet metal deburring and the removal of sharp edges, increasing workplace safety. Durable edge processing tools made from modern materials ensure longevity and efficiency in challenging industrial conditions. The company continuously invests in innovation, allowing it to maintain its leadership position in the market. Building customer relationships and tailoring products to their expectations is a key goal, contributing to user satisfaction and improving the quality of finished products.

Read more: Indoor Entrance Mats as a Floor Protection Element in Commercial Spaces

Types of Machines and Their Applications

Deburring machines offer a variety of models and configurations, allowing customization to specific customer needs. Choosing the right model is crucial for work efficiency, as each is designed with specific processing requirements in mind. Available are devices with various working widths and advanced technology options, such as CNC systems or automation. It's worth considering the offerings of Madora, a leader in sheet metal deburring. Thanks to innovative solutions and configuration possibilities, clients achieve high precision and efficiency in the deburring process.

Read more: What Are the Future Directions for Contract Manufacturing of Nutritional Supplements?

Workplace Safety

Modern deburring machines significantly enhance workplace safety by eliminating sharp edges that can lead to injuries. Precise sheet metal deburring and other processing operations greatly reduce the risk of accidents. These machines are designed with high safety standards, including robust construction and ease of use. Innovative technologies streamline processing operations, ensuring employee health in both the metal industry and other sectors.

Tool Materials and Technology

The durability and efficiency of edge processing tools are crucial for production efficiency. In the sheet metal deburring process, advanced materials are used to ensure longevity and effectiveness in challenging conditions. Scale removal disks and other machine components are made from high-quality, wear-resistant raw materials. Modern manufacturing methods enable precise tool production, translating into their efficiency. Investments in research and development allow companies like Madora to maintain competitiveness and tailor offerings to market needs.

Investments in Innovation

Investments in new technologies are crucial for maintaining competitiveness. Deburring machine manufacturers introduce innovations that significantly impact the development of the processing industry. Modern solutions allow for higher precision and efficiency in sheet metal deburring processes, resulting in better product quality. Companies like Madora invest in research and development to offer machines that meet customer expectations. The introduction of advanced processing technologies and metal deburring tools reflects the sector's dynamic growth and the market's increasing demands.

Building Customer Relationships

Customer satisfaction is a key goal for machine manufacturers. Companies build relationships through communication and technical support, allowing for a better understanding of customer needs. They adjust their products to expectations, offering the possibility to configure machines and innovative solutions. This approach enhances user satisfaction and improves the quality of finished products. As a result, enterprises gain recognition in both domestic and international markets, confirming the growing interest in them.