Sponsored article

Heat Sealers in Modern Production – Practical Applications and Technological Solutions

- What is Heat Sealing and When Should It Be Used?

- Advantages of the Process

- Construction of Heat Sealer Machines

- Typical Applications: From Blisters to Technical Textiles

- Blister and Blister-Card Packaging

- Medical Products

- Advertising and Coated Textiles

- Energy Efficiency and Process Automation

- Integration with Production Lines

- Comparison with Other Welding Technologies

- High-Frequency (HF) Welding

- Impulse Sealing

In the world of industrial materials bonding, precision, repeatability, and reliability are critical. Heat sealing has proven effective in demanding applications for years, and its advanced versions, available in modern machines, meet specific production needs. How does this technology work, where is it applied, and how does it stand out compared to other methods? Let's explore.

What is Heat Sealing and When Should It Be Used?

Heat sealing involves bonding materials using heated elements (typically molds or dies) that deliver controlled heat, maintaining a constant temperature throughout the working cycle. Unlike high-frequency methods, this technique does not require special dielectric properties of materials.

Advantages of the Process

-

Ability to achieve very precise seals with specific shapes,

-

Bonding materials of different thicknesses and structures,

-

No need for additional adhesives,

-

Repeatability and ease of automation.

This technology is suitable for both mass production and short runs, wherever the durability of the connection and high aesthetic quality are crucial.

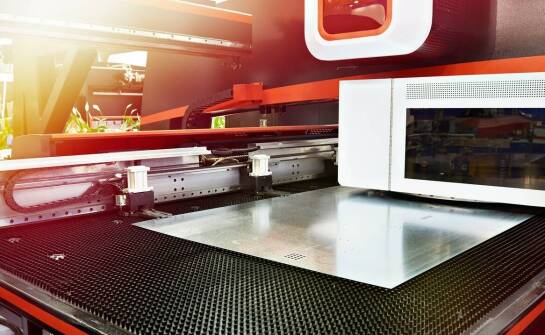

Construction of Heat Sealer Machines

Heat sealers are designed for maximum efficiency and precision. They feature a stable, steel frame that ensures rigidity and resistance to operational loads. A critical component is the heating plate—usually pneumatically controlled—with digitally regulated temperature based on material requirements. In modern devices, sealing can be automated or semi-automated, and operators can control parameters like time, pressure, and temperature. Many machines offer configuration with multiple workstations, increasing efficiency and streamlining cyclical production tasks.

Zemat Technology Group provides such solutions, combining years of experience with an innovative approach to machine design. The whole system is complemented by an intuitive interface and the possibility of expanding with additional tools and fixtures - all to ensure reliability, repeatability, and operational flexibility across various industries.

Typical Applications: From Blisters to Technical Textiles

Heat sealing technology finds applications in many industrial fields. It is particularly valued in the production of:

Blister and Blister-Card Packaging

Sealing PVC or PET film with cardboard creates aesthetic, durable, and recyclable packaging for consumer products. Machines can be equipped with quick-change systems for different blister formats and layouts.

Medical Products

Due to high repeatability and the ability to operate in sterile conditions, this technology is used to produce items like liquid pouches, masks, sterile tool packaging, and filters.

Advertising and Coated Textiles

In the coated materials sector, such as advertising banners or technical textiles, heat sealers enable adhesive-free bonding of layers. As a result, products are more resistant to weather conditions and aesthetically finished.

Energy Efficiency and Process Automation

Modern heat sealers are designed with high energy efficiency in mind. Maintaining a constant working temperature combined with precise time and pressure control minimizes power consumption without compromising seal quality.

Integration with Production Lines

In advanced production facilities, heat sealing machines are often integrated with systems for transporting, cutting, and quality control. This approach significantly increases efficiency and reduces material waste.

Comparison with Other Welding Technologies

While heat sealing has many advantages, it is also worthwhile to consider other technologies available on the market that may better meet specific production requirements.

High-Frequency (HF) Welding

HF technology uses electromagnetic field energy to generate heat within the material, enabling quick and uniform sealing. It is particularly effective for bonding dielectric materials such as PVC, TPU, and PU. HF welding machines are often used in the production of medical products, automotive components, and technical textiles.

Impulse Sealing

In impulse sealing, heat is generated by the flow of electrical current through a heating band only during the sealing moment. This method is characterized by low energy consumption and is ideal for sealing thin films and materials sensitive to temperature. Impulse sealers are used in applications such as vacuum packaging, foil packaging production, and the food and pharmaceutical industries.

Heat sealing is a proven method for precise and durable bonding of thermoplastic materials, regardless of material format or thickness. Due to its flexibility and the ability to customize machines for specific industries, this technology is excellent where repeatability, quality, and readiness for growth are paramount.